How CNC Routers Improve Accuracy and Production Efficiency

- zoehsewell

- Feb 5

- 5 min read

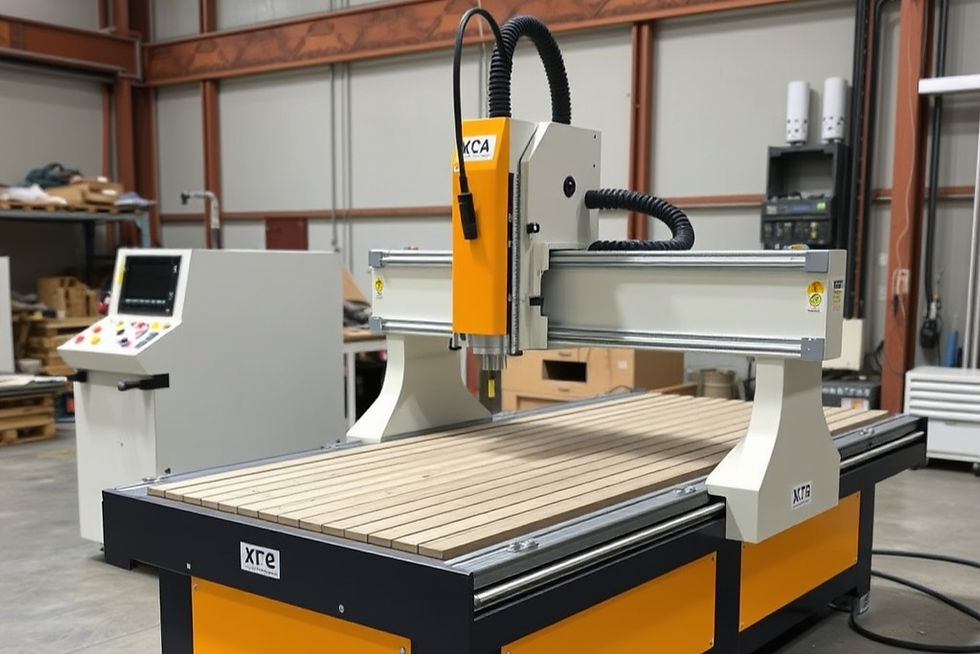

In modern manufacturing, precision and speed are no longer optional—they are essential. Businesses across woodworking, signage, furniture, and industrial manufacturing rely on CNC Routers to achieve consistent accuracy while increasing production efficiency. These advanced machines have transformed traditional fabrication methods by replacing manual guesswork with computer-controlled precision.

Whether you operate a small workshop or a large production facility, CNC Routers offer measurable benefits in quality control, material usage, turnaround time, and scalability. This guide explores how CNC Routers work, why they outperform manual methods, and how they help businesses improve accuracy and production efficiency without compromising quality.

What Are CNC Routers and How Do They Work?

CNC Routers are computer-controlled cutting machines used to carve, shape, and cut materials with exceptional accuracy. CNC stands for Computer Numerical Control, meaning every movement of the machine is guided by pre-programmed digital instructions.

The process begins with a design created using CAD (Computer-Aided Design) software. That design is converted into CAM (Computer-Aided Manufacturing) instructions, commonly known as G-code. CNC Routers then follow these instructions precisely, controlling cutting depth, speed, and tool movement across multiple axes.

Unlike manual routing, CNC Routers execute each operation exactly as programmed, ensuring consistent results from the first cut to the last.

How CNC Routers Improve Accuracy

Eliminating Human Error

One of the biggest advantages of CNC Routers is their ability to remove human error from the manufacturing process. Manual cutting relies heavily on operator skill, focus, and physical consistency. Even experienced craftsmen can make mistakes due to fatigue or mismeasurement.

CNC Routers follow programmed paths without deviation. Once the design is approved, the machine produces identical components repeatedly with minimal variation. This consistency dramatically improves accuracy and reduces costly rework.

Maintaining Tight Tolerances

Many industries require extremely tight tolerances, especially when parts must fit together precisely. CNC Routers are capable of maintaining tolerances as tight as ±0.1mm or better, depending on machine quality and material type.

This level of precision ensures that components align perfectly during assembly, reducing fitting issues and improving final product quality.

Digital Precision from Design to Production

With CNC Routers, what you design on screen is exactly what you get on the cutting table. Modern CAM software allows manufacturers to simulate tool paths before production begins, identifying potential errors early.

Any design change can be applied instantly by updating the digital file, eliminating the need for physical templates or manual recalibration.

How CNC Routers Increase Production Efficiency

Faster Production Speeds

Speed is a major factor in production efficiency, and CNC Routers operate far faster than manual routing methods. These machines maintain consistent cutting speeds without slowing down due to fatigue or loss of concentration.

Complex components that might take hours to cut manually can often be completed in minutes using CNC Routers. Many businesses also operate CNC Routers continuously, including overnight runs, to maximise output without increasing labour costs.

Reduced Setup and Changeover Time

Traditional manufacturing often requires time-consuming setup for each new job. CNC Routers reduce this significantly by storing programs digitally.

Once a program is created, it can be reused for repeat orders with minimal setup time. This is especially beneficial for businesses handling batch production or ongoing contracts.

Improved Workflow Automation

CNC Routers integrate seamlessly with modern production workflows. From design to cutting, the entire process can be streamlined digitally. This automation reduces bottlenecks, improves scheduling accuracy, and ensures consistent production output.

Reducing Material Waste with CNC Routers

Optimised Cutting Paths

Material waste is a major cost factor in manufacturing. CNC Routers use advanced nesting software to optimise how parts are arranged on a sheet of material.

By positioning components efficiently, CNC Routers minimise offcuts and maximise material usage. Many manufacturers report material savings of 10% to 20% after switching to CNC routing.

Fewer Errors and Rejected Parts

Manual mistakes lead to rejected parts and wasted materials. CNC Routers significantly reduce these errors by following exact instructions every time.

This accuracy not only saves material but also reduces disposal costs and improves sustainability efforts.

Materials Commonly Cut with CNC Routers

Wood and Timber Products

Wood remains one of the most common materials processed by CNC Routers. From solid timber to MDF and plywood, CNC Routers deliver smooth finishes and precise cuts suitable for furniture, cabinetry, and joinery.

Plastics and Acrylics

CNC Routers are widely used in signage and display manufacturing to cut acrylic, polycarbonate, and other plastics. These materials benefit from clean edges and consistent shapes achieved through CNC routing.

Aluminium and Soft Metals

Many modern CNC Routers can also machine aluminium and other soft metals. With the right tooling and cutting parameters, CNC Routers produce accurate metal components used in industrial applications.

Composite Materials

Advanced CNC Routers handle composite materials such as fibreglass and carbon fibre. These materials require precise cutting strategies, which CNC Routers execute reliably.

CNC Routers vs Traditional Manufacturing Methods

Limitations of Manual Routing

Manual routing depends heavily on operator experience and physical precision. While suitable for one-off custom work, it struggles with repeatability, speed, and consistency in production environments.

Operator fatigue, setup variations, and measurement errors make it difficult to achieve uniform results across large batches.

Why Businesses Are Switching to CNC Routers

CNC Routers offer repeatable accuracy, faster production, and reduced labour dependency. As skilled manual labour becomes harder to find, CNC Routers help businesses maintain quality while addressing workforce challenges.

Modern CNC Routers are also more affordable than ever, making them accessible to small and medium-sized workshops.

Industries That Benefit Most from CNC Routers

Furniture and Cabinet Manufacturing

Furniture makers rely on CNC Routers to produce precision components, intricate joinery, and decorative features consistently. This improves efficiency and ensures uniform product quality.

Signage and Display Production

Signage manufacturers use CNC Routers to cut detailed shapes and lettering from various materials. Tight deadlines and high visual standards make CNC Routers essential in this industry.

Automotive and Aerospace Applications

In industries where accuracy is critical, CNC Routers produce jigs, moulds, and composite parts with exact specifications, supporting high-performance manufacturing standards.

Are CNC Routers Worth the Investment?

For many businesses, CNC Routers deliver a strong return on investment. Reduced labour costs, faster turnaround times, lower material waste, and improved product consistency all contribute to long-term savings.

Small businesses producing repeat components often recover their investment faster than expected, especially when factoring in reduced rework and increased capacity.

Maximising Accuracy and Efficiency with CNC Routers

Optimising Tooling and Programming

Using the right cutting tools and optimised tool paths significantly improves CNC Router performance. Efficient programming reduces machining time while maintaining surface quality.

Regular Maintenance

Routine maintenance keeps CNC Routers operating at peak accuracy. Cleaning, lubrication, and calibration prevent breakdowns and extend machine lifespan.

Operator Training

While CNC Routers automate cutting, skilled operators are still essential. Proper training ensures correct setup, programming, and troubleshooting for maximum efficiency.

The Future of Manufacturing with CNC Routers

As technology evolves, CNC Routers continue to become faster, smarter, and more accessible. Integration with automation systems, AI-driven optimisation, and advanced software will further improve accuracy and production efficiency.

For manufacturers looking to stay competitive in 2026 and beyond, CNC Routers are not just a tool—they are a strategic investment in quality, scalability, and long-term growth.

Final Thoughts

CNC Routers have redefined what’s possible in modern manufacturing. By delivering unmatched accuracy, reducing waste, and dramatically improving production efficiency, CNC Routers empower businesses to produce better products faster and more consistently.

Whether you are upgrading from manual methods or expanding production capacity, CNC Routers provide the precision and efficiency needed to succeed in today’s competitive market.

Comments